PVDC, with its scientific name "polyvinylidene chloride", is a thermoplastic polymer with a softening temperature ranging from 160 to 200℃

What is PVDC?

PVDC,学名“聚偏氯乙烯”,是一种热塑性聚合物,软化温度为160~200℃,具有首尾相连的线性聚合物链结构,分子结构对称,结晶性高。对于PVDC来说,由于其分子间内聚力强,结晶性高,PVDC分子中的氯原子具有疏水性,不会形成氢键,具有良好的阻氧、阻湿性能,其阻氧性能不受环境湿度的影响。也就是说,在任何温度或湿度条件下,PDVC对水蒸气、氧气、臭味和香味都有着优异的阻隔能力,是目前公认阻隔性方面综合性能最好的塑料包装材料。

Characteristics of PVDC

Polyvinyl chloride/polyvinylidene chloride (PVC/PVDC) pharmaceutical composite hard films are used for blister packaging of solid medications (tablets, capsules). Compared to PVC films, PVC/PVDC pharmaceutical composite hard films exhibit superior moisture and oxygen resistance, as shown in Table 1.

PVDC and pharmacy packaging

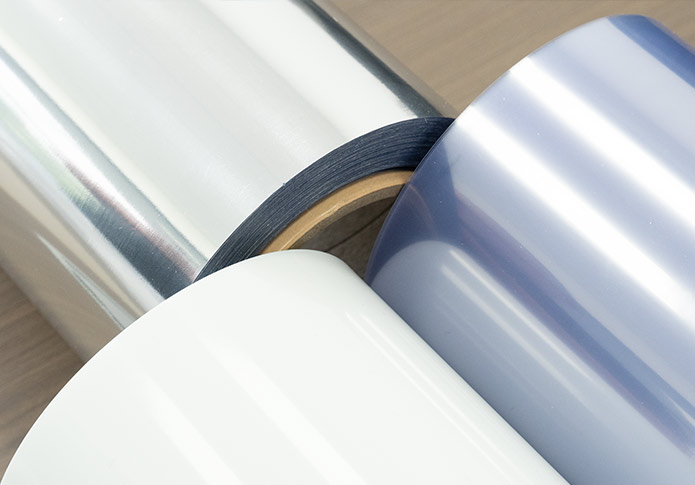

PVDC-coated composite materials, as high-barrier packaging materials for pharmaceuticals, are most commonly used to make pharmaceutical blister packaging, granules, and powder composite packaging bags. The mechanical properties and certain physical properties of the coating material are determined by the substrate, while the barrier properties, aroma retention, oil resistance, etc. are determined by the coating layer. To find suitable packaging materials, procurement personnel only need to think clearly about what they want to package and in what context. The substrate used for blister packaging is PVC sheet, while the substrate used for granules and powder composite packaging bags is BOPET or BOPP film.

Back to list